My fellow eBayers have been snoozing a bit of late, and I have snapped up some really nice Mafac brakes in the last little while for very little money.

"Racer"s are very nice and easy to find—but for reasons I don't quite understand (perhaps just because they're hard to find; or maybe it's the brass bushings) I like all the other ones best. And in the last couple of weeks, I have purchased almost every one of them, as the photo at right demonstrates.

And now, individual photos:

Mafac 2000s — Third Version

These are New Old Stock and very shiny. They also have those cool wheel guides. This is the third version: the first was engraved; the second had the other style of straddle cable. I don't know what I'll use these for, but I'm sure I'll find a use...

These came in their original box, which is a prize in its own right!

Mafac Competitions — Second Version

Also New Old Sock. Exactly like the 2000s, except they have shorter reach (and the earlier straddle cable). These are really gorgeous, and are going on Greg Curnoe Bike.

Mafac Competitions — First Version

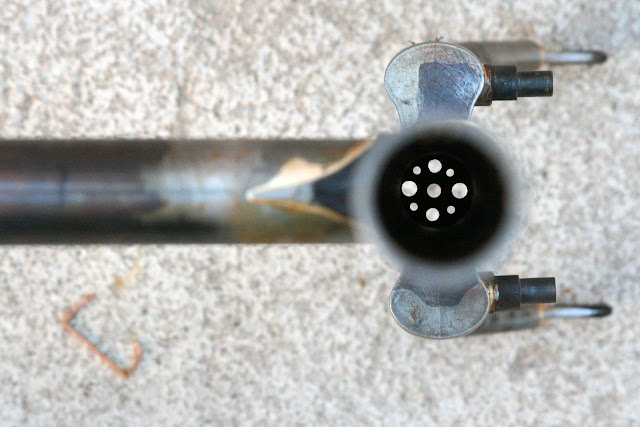

The engraving gives these away as the older models. They're used but in really good shape. I got a pair, but I'll only use one—for Monty's front brake. Perhaps I'll build another fixed gear bike some day, and use the other one for that... Here's a picture of this brake on Monty's fork:

Mafac Criterium Cantilevers — Blue Anodized

Who knew such things existed! New Old Stock, and they even cane with original Mafac braze-ons, marked "AV" and "AR" for avant and arrière. I think I'll use these on the bike I'm planning for my girlfriend, "Kitten Paradise," which will be extremely colourful.

Also in my collection, though not purchased recently, are my...

Mafac Raids

These are also New Old Stock. And while not as pretty as the other centrepulls, extremely hard to track down, and certainly an exciting brake in their way. As soon as I'm competent with "advanced" framebuilding skills like squeezing massive tires into short chainstays, I'll build a 650B bike with these brakes.

The Raids are really huge. They eat Competitions for breakfast.

I have also recently purchased a really nice 48T Campagnolo Pista chainring, with the idea of using it on Monty. I have a pair of Campagnolo Strada 170 cranks which with a bit of filing would become identical to a pair of Pistas. But soon after I got that ring, I came across a very cheap TA 48T track ring. It looks pretty nice on this Stronglight 49D crank arm (whose spider is awfully out of true—I'll try to fix it, but it's pretty bad.)

Which do you prefer? I'm leaning toward the Campagnolo, though it requires filing my cranks (always feels a bit like a crime), and the TA/Stronglight combo is noticeably lighter.